A self-contained environmentally friendly cleaning system for construction plant and equipment. The X-2 comes with the X-10 Filtration Tank as standard

• The closed loop system allows you to recycle water and prevents contaminated water from

entering the drainage system

• Less water is used which means money is saved on water bills and discharge licences

• Easy to transport and assemble

• Modular design allows for greater flexibility to meet customer specific applications

• Environmentally friendly

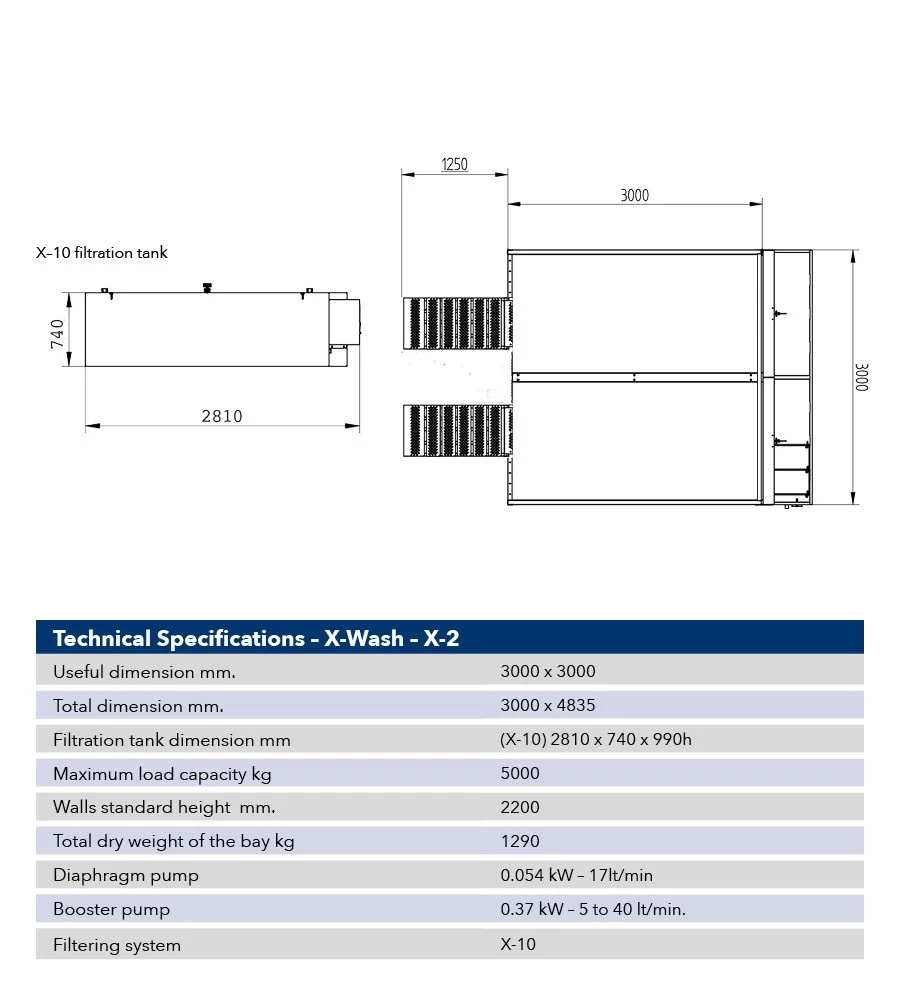

The X-2 wash area is approx. 3000mm wide and 3000mm deep and comprises two modular base sections 1500mm x 3000mm. The wash area is accessible via two galvanised anti slip ramps as standard. To reduce the risk of overspray the X-2 has 2200mm high walls on three sides. More ramps can be ordered as an option. The washbay floor pan directs dirty water and any solids towards the rear of the wash area and into a solids collection tank. Inside the rear solids collection tank are three dams that retain the solids but allow the water to filter through towards an outlet. At the outlet end of the rear collection tank is a float switch. When the water reaches a specified level the float switch activates a diaphragm pump housed in the Filtration Tank. This pump then sucks the liquid out of the solids collection tank into the Filtration Tank. The Filtration Tank then through the use of a number of filters and weirs filters out the remaining contaminants and lightly chlorinates the liquid leaving the clean water ready to be reused in the washbay. All the filters are easily removed and replaced to ensure continuity of service. When the end user operates their pressure washer the booster pump housed within the filtration tank activates to supply the pressure washer with water as required.

TRIME s.r.l. - © copyright 2023 - All right reserved - P. IVA 00541350187